Chiller o Condensadora: ¿Cuál Elegir?

¿Cuándo Elegir un Chiller y Cuándo una Condensadora para tu Edificio o Proceso Industrial?

En el ámbito del Facility Management, la climatización no se limita a mantener cómodos los espacios de una oficina. Es un pilar fundamental para la eficiencia operativa, la productividad y, en muchos casos, la viabilidad de procesos industriales críticos.

Una de las decisiones más cruciales al diseñar o renovar un sistema de enfriamiento es elegir entre un chiller (enfriadora de líquido) y una condensadora.

Esta elección, lejos de ser arbitraria, depende de múltiples factores específicos de tu edificio o proceso.

Entendiendo la Base: Chiller vs. Condensadora

Aunque ambos sistemas tienen como objetivo final el enfriamiento, operan bajo principios y escalas diferentes:

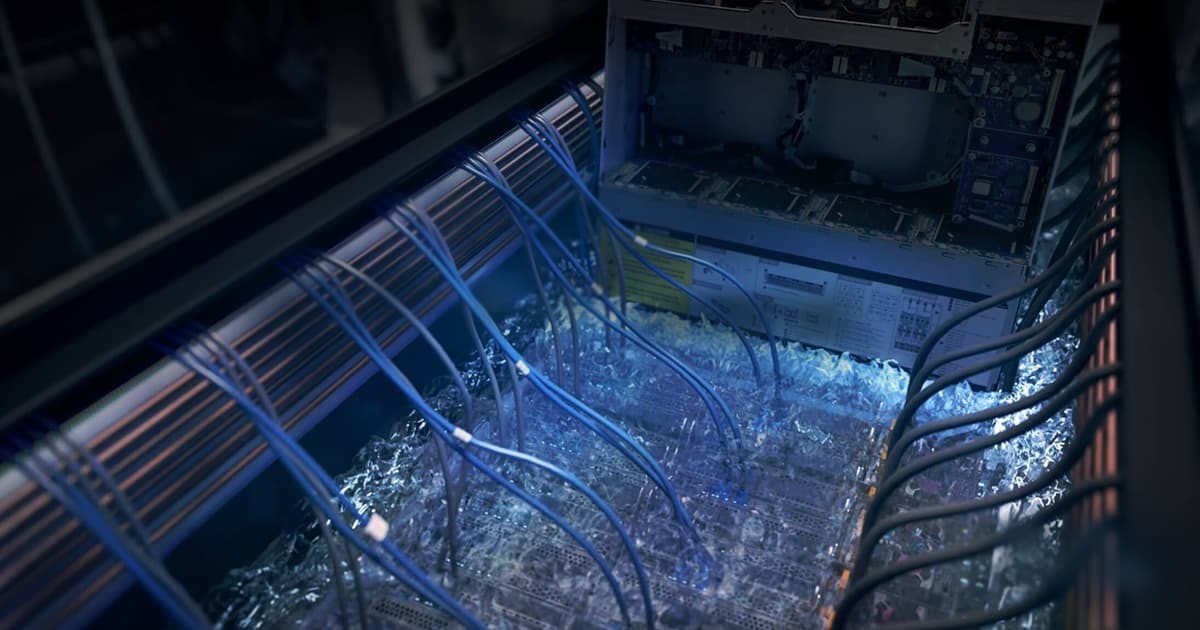

- Chiller (Enfriadora de Líquido): Es una máquina centralizada que enfría un líquido (generalmente agua o una solución de glicol). Este líquido frío se bombea a través de tuberías a unidades terminales (como unidades manejadoras de aire – UMAs, fan coils o intercambiadores de calor en procesos industriales) donde absorbe el calor del ambiente o del proceso. Los chillers son sistemas de alta capacidad y ofrecen gran precisión en el control de la temperatura del líquido.

- Condensadora (Unidad Condensadora): Es un componente clave de un sistema de refrigeración por expansión directa (DX). Contiene el compresor, el serpentín del condensador y el ventilador que expulsa el calor al exterior. Trabaja en conjunto con una unidad evaporadora (interior) a la que envía refrigerante comprimido. El refrigerante absorbe calor directamente del aire interior en la unidad evaporadora.

Factores Clave para la Decisión

La elección entre uno u otro sistema no es universal y debe basarse en un análisis detallado de los siguientes puntos:

- Capacidad y Escala:

- Chiller: Ideal para grandes cargas térmicas y edificios de gran envergadura (hospitales, centros comerciales, hoteles, universidades) o procesos industriales que requieren enfriamiento masivo y continuo.

- Condensadora: Más adecuada para cargas térmicas medianas a pequeñas, como oficinas individuales, locales comerciales, residencias multifamiliares o sistemas de climatización por zonas (splits, VRF/VRV).

- Tipo de Aplicación y Precisión:

- Chiller: Ofrecen un control de temperatura más preciso y estable del líquido enfriado, lo que es fundamental para muchos procesos industriales (farmacéutico, químico, plástico, alimentos y bebidas) y para edificios con requerimientos de confort muy específicos.

- Condensadora: Si bien son eficientes, la precisión en el control de temperatura del aire puede ser ligeramente menor comparada con un sistema de agua helada bien diseñado, aunque suficiente para la mayoría de las aplicaciones de confort.

- Distribución y Flexibilidad:

- Chiller: Al usar agua fría, permite una distribución más flexible a través de tuberías y una gran variedad de unidades terminales (UMAs, fan coils). Facilita la zonificación y la expansión futura del sistema.

- Condensadora: Funciona con refrigerante, lo que implica limitaciones en la longitud de las tuberías y la cantidad de unidades interiores por unidad exterior. Son menos flexibles para grandes distancias o distribuciones complejas.

- Eficiencia Energética y Costos Operativos:

- Chiller: Los chillers de gran capacidad pueden ser extremadamente eficientes energéticamente, especialmente si se integran con sistemas de recuperación de calor o enfriamiento gratuito (free cooling). Suelen tener una vida útil más larga.

- Condensadora: Los sistemas de expansión directa (DX) han mejorado mucho su eficiencia (SEER/EER), pero en cargas parciales o muy grandes, un chiller bien gestionado puede ser más eficiente a largo plazo. Los costos de mantenimiento pueden ser menores si son unidades pequeñas.

- Costo Inicial y Mantenimiento:

- Chiller: La inversión inicial es considerablemente más alta debido a la complejidad del equipo (chiller, bombas, torre de enfriamiento, tuberías, UMAs). El mantenimiento es más especializado.

- Condensadora: Generalmente tienen un menor costo de adquisición e instalación para aplicaciones de menor escala. El mantenimiento suele ser más sencillo y menos costoso en unidades individuales.

- Sustentabilidad y Refrigerantes:

- Chiller: Los sistemas de agua fría tienen la ventaja de que el refrigerante (con alto potencial de calentamiento global – GWP) está confinado en el chiller, minimizando el riesgo de fugas a gran escala.

- Condensadora: El refrigerante circula por todo el edificio, aumentando el potencial de fugas. Sin embargo, se están desarrollando refrigerantes con menor GWP para estos sistemas.

¿Cuándo Elegir un Chiller?

- Cuando la demanda de enfriamiento es muy alta y constante.

- En edificios grandes o complejos con múltiples zonas de enfriamiento y necesidades variadas.

- Para procesos industriales que requieren temperaturas precisas y controladas.

- Si se busca una alta eficiencia energética a gran escala y se dispone de presupuesto para la inversión inicial.

- Cuando la flexibilidad en la distribución del enfriamiento y la futura expansión son prioritarias.

¿Cuándo Elegir una Condensadora?

- Para edificios de tamaño pequeño a mediano con una demanda de enfriamiento moderada.

- Si se opta por sistemas de expansión directa (split, multisplit, VRF/VRV) que ofrecen enfriamiento directo del aire.

- Cuando el presupuesto inicial es más ajustado y la instalación debe ser más sencilla.

- En proyectos donde la distancia entre la unidad exterior y las interiores no es excesivamente grande.

- Si la precisión extrema en el control de la temperatura no es un requisito crítico.

La decisión entre un chiller y una condensadora es estratégica y debe ser abordada desde una perspectiva integral de Facility Management.

No existe una solución única para todos.

Requiere un análisis profundo de las necesidades específicas de tu edificio o proceso, el presupuesto disponible, las metas de eficiencia energética, la vida útil esperada y las regulaciones ambientales.

Consultar con expertos en climatización y Facility Management es fundamental para garantizar una elección que optimice el confort, la productividad y el retorno de la inversión a largo plazo.